Electric Motors

According to Fink and Beaty, authors of Standard Handbook for Electrical Engineers, most industrial machinery is driven by electric motors. Industries would ease to function without properly designed, installed and maintained motor control systems. These electric motor driven systems that convert electric energy to rotating mechanical functions for use in such devices such as pumps, fans and compressors.

Classification of Motors According to Type of Power Used

- Alternating Current (AC) Motor

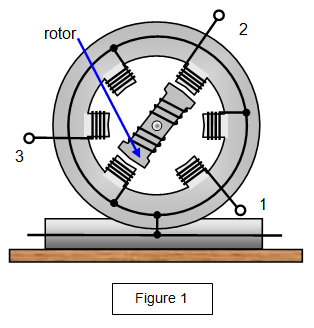

The rotating part of an AC motor is referred to as the rotor; the stationary part of the motor is referred as the stator. A squirrel-cage rotor consists of an laminated steel core with conductors cast into the rotor slots. All AC motors are classified according to the type of AC power used. Either single-phase or three-phase (polyphase).

AC motors (alternating current) is a very wide class of motors, including single / multi phase, universal, servo, induction, synchronous, and gear motor types. The magnetic field, generated by AC motors, is produced by an electromagnet powered by the same AC voltage as the motor coil. The coils that produce the magnetic field are traditionally called the "field coils" while the coils and the solid core that rotates is called the "armature.” There are many advantages in the use of ac motors aside from the wide availability of AC power. In general, AC motors cost less than DC motors.

There are two distinct types of AC motors, 1. synchronous and 2. induction.

A synchronous motor consists of a series of three windings in the stator section with a simple rotating area. A current is passed through the coil, generating torque on the coil. Since the current is alternating, the motor will run smoothly only at the frequency of the sine wave. This allows for constant, unvarying speed from no load to full load with no slip.

Induction motors are the more common of the two motor types. They use electric current to induce rotation in the coils rather than supplying the rotation directly. Induction motors use shorted wire loops on a rotating armature and obtain their torque from currents induced in these loops by the changing magnetic field produced in the field coils.

- Direct Current (DC) Motor

Direct current motors are used in a wide variety of industry applications because of the ease with which the speed can be controlled. The speed control characteristic may be varied to almost any useful form. The rotating part of the motor is referred to as the armature, the stationary part of the motor is referred to as the stator, which contains the series field wind and the shunt field winding. Speed of a DC motor is controlled either by voltage across the armature, the field winding or both.

Del Rosario (2004) developed a microprocessor-based automated beverage mixer that uses different direct current motors in dispensing and for linear movement due to its speed control characteristic that can be applied in many different application just like in dispensing different mixtures of coffee. Also due to its ability to be connected directly to a control. Photo source

Classification of DC Motor

- Shunt Motor - In which the field winding is connected in parallel of the armature. DC shunt motor is suitable for application where constant speed needed at any control setting or where appreciable speed range (by field control) is needed.

- Series Motor - The field winding is connected in series with the armature. The series motor is used in applications where a high starting torque is required like in electric traction, cranes and hoists etc.

- Compound Motor - In which has a series-field and shunt-field winding. The compound motor is used in constant speed applications such as drives for dc generators in dc motor generator sets. The droop of the speed characteristic maybe adjusted to suit the load.

References:

Fink, Donald G. and H. Wayne Beaty (1993). Standard Handbook for Electrical Engineers. Singapore: McGraw-Hill Inc.

Del Rosario, Amiel G. (September 2004). Development of A Micro Processor Based Automated Beverage Mixer. Masteral Research Project

Fink, Donald G. and H. Wayne Beaty (1993). Standard Handbook for Electrical Engineers. Singapore: McGraw-Hill Inc.

Del Rosario, Amiel G. (September 2004). Development of A Micro Processor Based Automated Beverage Mixer. Masteral Research Project

No comments:

Post a Comment