AUTOMATION

According to Bame and Cummings, authors of Exploring Technology, total automation occurs when a process is completed without human control. A process rarely occurs without any human control at all. Usually some human control is involved. Automation is automatic control.

As Avila (May 2002) developed an AS2 automatic sprayer (an innovation). The answer for more effective and much convenient spraying. The main component used is same with the manual garden sprayer. There are some additional materials used to complete the project. AS2 automatic sprayer was developed to lessen the stress of the user in pumping the sprayer to create the pressure. It has an ability to pump in an automatically and when it reached the highest operating procedure, it will shut off and resume pumping when the pressure drops at the lowest operating pressure.

The sprayer has safety relief valve and emergency stop switch. It can refill solvent without releasing the pressurized air inside the sprayer. It can be carried by backpack or by using a trolley.

Example of an Automated Sprayer

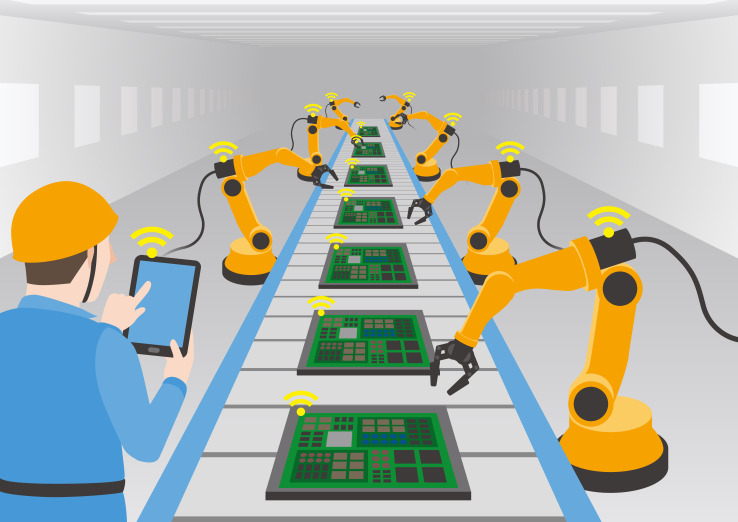

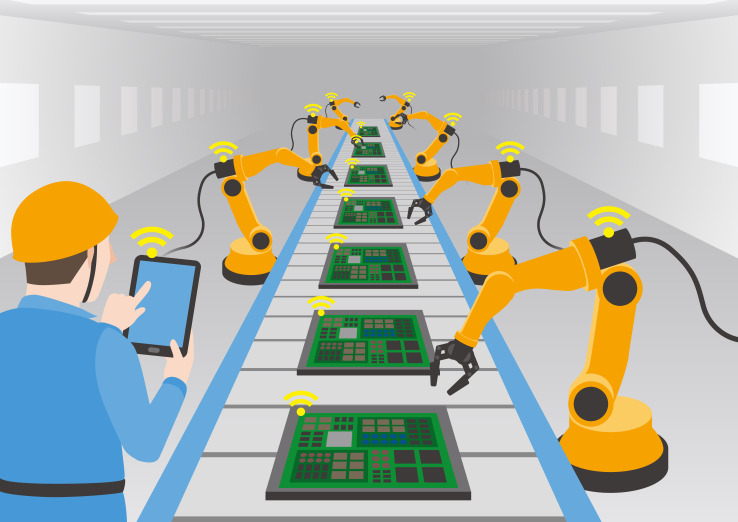

When a factory, assembly line, or some process is automated, machines are used in place of human labor. Parts are moved on assembly lines. A work-piece—work being manufactured—is fed into a machine automatically. Work is done on the piece, and it is moved to another machine. All this is done without human intervention.

Automation makes work easier and faster. One reason Soriano (March 2003) developed a printed circuit board-etching machine, which intends to make the etching process faster and easier. The agitating machine is detachable wherein you can replace the basin corresponding to the size of your PCB (Printed Circuit Board). It has a timer where you can set at approximately five minutes and 38 sec. It has also a buzzer and light emitting diode (LED) that indicates that it has finished the desired time. It has an adjustable holder that allows the use of different size of PCB. It operates horizontally towards the basin and allows the vertical action of the PCB towards the ferric chloride during the etching process. Agitating machine provides not only convenience to users but also saves time, effort, money, space and energy.

The equipment was evaluated by panel of experts in electronics and mechanical. To the evaluators, the agitating machine is highly acceptable in terms of operation, safety in electrical, mechanical and chemical solution. They also gave an acceptable rating to materials used and durability. On the overall, the equipment is highly acceptable. The project was also evaluated by end users and found to be highly acceptable. They perceived the equipment will help save time, effort, space and energy in etching process.

Another way of describing automation is by saying it is automatic regulation. Automation is important to human technology. It undoubtedly will be important in the future. Automation can be found in nearly all areas of technology. Our first thoughts about automation may be of automated assembly lines with robots doing the work of humans. But, actually, automation can be found more often in other areas.

The machining of metal was among the first processes to be mechanized and then automated. Machine tools were first controlled by punched tape. There was no feedback. The tape merely controlled the location and cutting action of the cutter.

These machines are called numerically-controlled (NC) machines. Each hole (or combination of holes) in the represent the command to the machine. Sensors detect the holes. A message is sent to the controls on the machine causing it to move in a certain way. Magnetic tape similar to that use in tape recorders replaced most punched-tape in NC machines. Today computers control these automated machines. This is called Computer Numerical Control (CNC). CNC machines can store and transmit large quantities of very complex information. They are capable of doing very complicated tasks.

Example of a CNC machine

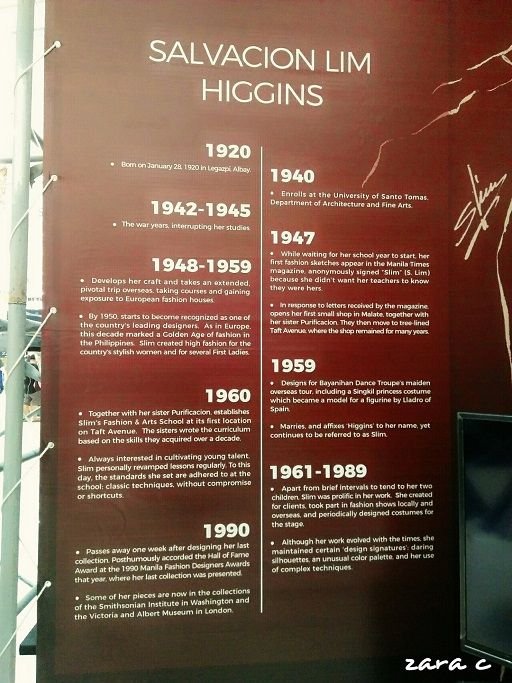

Historical Development of Automation

Time ----- Development

1642 - Blaise Pascal’s arithmetical engine

1788 - James Watt’s centrifugal or fly-ball governor. Regulates the speed and power of steam engines.

1790 - Oliver Evan’s “automated” flour making factory.

Mechanical devices move the raw materials through the various flour-making steps to filling the bags.

1801 - Jacquard’s automated loom. Movements of many Shuttles are controlled by punched cards to produce

intricate patterns in the cloth.

1822 - Charles Babbage’s analytical engine. Eventually leads to the development of the computers.

1884 - Hollerith’s census machine

1923 - Capek wrote the play R.U.R.

1946 - D.S. Harder of the Ford Motor Co. originated the word “automation”.

1946 - First generation of computers begins.

1950 - Norbert Wiener publishers The Human Use of Humans –predicts automatic controls would make the

Automatic factory a reality within 25 years.

1956 - Work by Engelberger and Devol leads to the formation of the Unimation Company.

1960 - First Industrial robot built.

1961 - Unimation company builds “Ultimate” it’s first industrial

1969 - Computers begin to be used to control industrial processes in Britain.

197? - PUMA-first robot designed exclusively to assemble the parts of computers and motors.

1986 - An essential 26,400 robots have been installed in thenUnited States. About 1,685 of these have vision.

Image Sources:

- https://techcrunch.com/2016/04/21/the-automation-revolution-and-the-rise-of-the-creative-economy/

- https://www.aliexpress.com/store/product/ABS-Engineering-Plastic-360-Degree-Rotating-Sprinkler-Mobile-Automatic-Garden-Lawn-Irrigation-Sprayer-Gardening-Water-Nozzle/315621_2025438958.html

- https://www.quora.com/What-is-the-use-of-CNC-machines#!n=18

References

- Bame, Allen and Paul Cummings (1998). Exploring Technology. U.S.A.: Delmar Publishers, Inc.

- Fu, K.S. and R.C. Gonzales (1987). Robotics. Singapore: Chong Moh Offset Printing Pte Ltd.

- Avila, Nathanael (May 2002). AS2 Automatic Sprayer.

- Soriano, Louie V. (March 2003). Development of an Printed Circuit Board Etching Machine. Masteral Research Project